5 Things You Didn’t Know About the Longevity of Rubber Keypads

Exploring the Production Refine Behind Rubber Keypads and Their Relevance in Modern Gadgets

Rubber keypads are essential in the functionality of modern-day tools. Their production procedure involves mindful selection of materials and precise techniques. Keypads are developed to boost customer interaction while making sure sturdiness and reliability. Recognizing how these parts are made discloses their relevance throughout different applications. What factors add to their efficiency, and exactly how do these components influence customer experience? The answers may reshape assumptions of this daily modern technology.

Introduction of Rubber Keypads and Their Applications

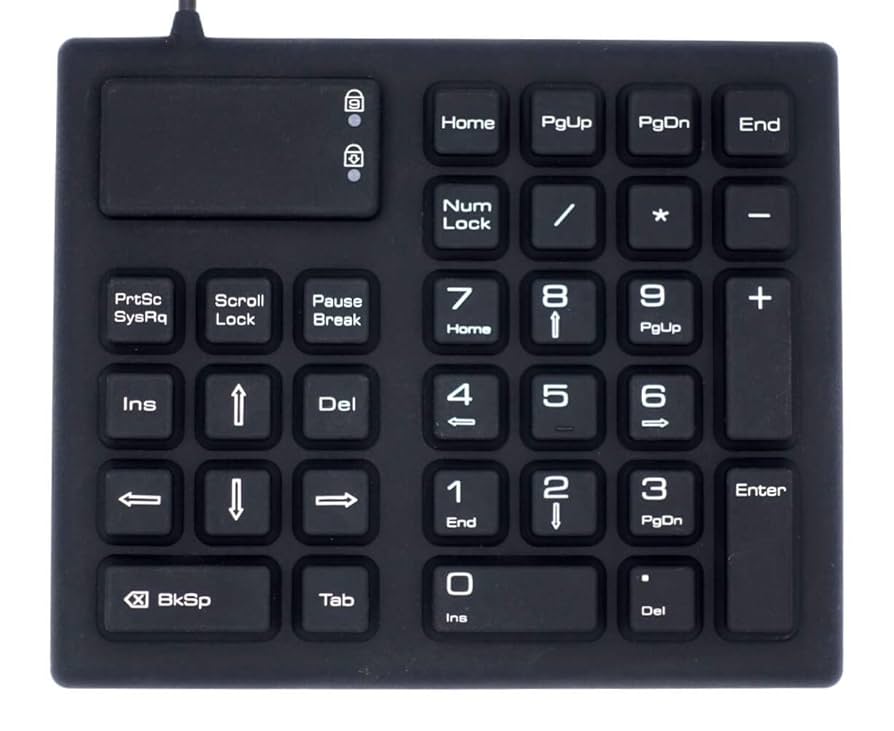

Rubber keypads are flexible components commonly utilized in numerous electronic gadgets, ranging from consumer electronics to industrial devices. Their style enables for a responsive action, making them an optimal choice for applications requiring user communication. Generally found in products such as push-button controls, calculators, and medical tools, rubber keypads facilitate simplicity of usage and accessibility.

In industrial settings, they offer vital features in machinery and control panels, where sturdiness and resistance to environmental aspects are necessary. The non-slip surface improves grasp, advertising integrity in demanding problems. Additionally, their light-weight nature and adjustable forms allow producers to produce tailored remedies that fit details needs. With advancements in modern technology, rubber keypads continue to progress, including functions like backlighting and enhanced sensitivity. Overall, their flexibility and useful advantages add greatly to the efficiency of different devices across numerous industries.

Materials Made Use Of in Rubber Keypad Manufacturing

Keypad producing depends on an option of materials that improve both performance and resilience. The key product made use of in the manufacturing of rubber keypads is silicone rubber, understood for its outstanding durability and versatility. This product enables keypads to withstand duplicated pushing without shedding form or performance. Additionally, thermoplastic elastomers (TPE) are often utilized due to their convenience of molding and capacity to give a soft-touch feeling.

Tinting agents, such as pigments, are incorporated to ensure lively, resilient shades that improve aesthetic charm. Additionally, additives like anti-UV representatives and fire retardants may be blended into the rubber to boost weather condition resistance and safety compliance. The selection of products straight influences the keypad's tactile feedback, longevity, and total efficiency in numerous tools. Ultimately, the careful choice of these components is essential for the production of top quality rubber keypads that satisfy consumer and sector demands.

The Layout Process of Rubber Keypads

When producing rubber keypads, the design procedure plays a crucial function in identifying functionality and individual experience. Developers start by specifying the keypad's intended use, taking into consideration factors such as the tool it will come with and the target individual demographic. This first phase includes mapping out layouts that prioritize ergonomic aspects, making certain the tricks are conveniently available and suitably spaced.

Next off, developers concentrate on the tactile feedback desired from the keypads, which affects the option of materials and crucial shapes. Prototyping is important in this stage, enabling designers to check different designs for convenience and responsiveness.

Production Techniques for Rubber Keypads

The production procedure for rubber keypads entails a series of accurate methods that guarantee quality and functionality. Fluid silicone rubber (LSR) is commonly made use of due to its durability and flexibility. The process starts with blending the raw products, consisting of silicone, colorants, and healing representatives. This blend is then infused into molds designed to form the keypads properly.

Following shot, the molded keypads undertake healing, a home heating procedure that strengthens the product (Rubber Keypads). This is normally done in a press, making certain the keypads accomplish the desired firmness and strength

Quality Assurance Measures in Manufacturing

To ensure that rubber keypads meet high criteria of top quality and performance, extensive quality control procedures are applied throughout the production procedure. These measures begin with raw product examination, guaranteeing that just the highest-grade elastomers are utilized. During the manufacturing phase, operators carry out regular checks to monitor specifications such as temperature level, stress, and blending times, essential for achieving constant product high quality.

Post-production, each batch of keypads goes through comprehensive testing, consisting of tactile reaction assessments and sturdiness tests to assess efficiency under various problems. Aesthetic assessments are also carried out to determine any type of flaws, such as bubbles or incongruities in texture. In addition, compliance with industry criteria is verified, guaranteeing that the keypads satisfy safety and functionality standards.

The Duty of Modern Technology in Keypad Advancement

Innovation plays an important duty in the growth of rubber keypads by enabling sophisticated manufacturing methods that enhance accuracy and effectiveness. Additionally, ingenious product option allows for boosted resilience and responsiveness in keypad efficiency. These developments not only streamline manufacturing however also raise the overall top quality of the end product.

Advanced Manufacturing Techniques

Advancements in production techniques reinvent the manufacturing of rubber keypads, improving both effectiveness and precision. Technologies such as injection molding and 3D printing have transformed traditional processes, making it possible for manufacturers to produce complicated styles with decreased waste and enhanced turnaround times. Automation plays an important function in visit here this advancement, improving assembly lines and minimizing human mistake. In addition, computer-aided style (CAD) software program allows for intricate modification, guaranteeing that keypads meet specific individual needs. Quality control actions have also advanced, including real-time monitoring systems that detect defects early in the production cycle. These developments not just enhance the resilience and capability of rubber keypads yet likewise sustain the expanding demand for customized solutions in different sectors, from customer electronics to vehicle applications.

Cutting-edge Material Option

The evolution of producing strategies has led the way for cutting-edge product choice in rubber keypad development. Advancements in polymer science have actually presented materials that improve longevity, versatility, and responsive feedback. Manufacturers currently make use of thermoplastic elastomers (TPE) and silicone substances, which supply superior resistance to put on and environmental variables. These materials enable the production of keypads that can sustain long term usage while maintaining visual charm. In addition, the integration of layers and additives improves performance, such as improving grasp and minimizing rubbing. The choice of products is essential, as it directly affects the performance and long life of keypads in various tools, from customer electronics to industrial equipment. This cutting-edge method remains to shape the future of keypad design and use.

The Impact of Rubber Keypads on Customer Experience

Rubber keypads substantially influence customer experience with their enhanced responsive reaction, which permits more exact communication. In addition, their toughness and longevity add to consistent performance with time, minimizing the demand for regular substitutes. This mix of features makes rubber keypads a favored choice in different applications, inevitably affecting user satisfaction.

Improved Tactile Response

Enhancing responsive response significantly affects individual experience, especially in gadgets that rely on keypads for interaction. Rubber keypads supply a distinct mix of softness see it here and strength, permitting customers to really feel distinctive comments with each press. This responses reinforces a sense of control and accuracy, vital in applications varying from mobile phones to industrial tools. Individuals typically report higher complete satisfaction and performance when engaging with gadgets that feature well-designed rubber keypads, as they facilitate quicker and more accurate input. Additionally, the ergonomic layout of these keypads can lower finger tiredness, advertising longer use periods without pain. On the whole, the enhanced responsive response provided by rubber keypads substantially contributes to a more pleasurable and instinctive user experience in contemporary technology.

Resilience and Longevity

A key facet of individual experience with rubber keypads depends on their longevity and longevity. These keypads are made to endure substantial usage, resisting deterioration that typically affects various other materials. The robust nature of rubber guarantees that keypads keep their performance and look gradually, which is vital for tools often used in different environments. Users take advantage of the integrity of rubber keypads, as they can endure direct exposure to dust, temperature, and dampness fluctuations without wearing away. This durability not just boosts individual fulfillment yet likewise minimizes the demand for regular replacements, inevitably adding to cost-effectiveness for suppliers. Essentially, the sturdiness of rubber keypads substantially influences the general performance and user experience in modern-day devices.

Frequently Asked Concerns

How Much Time Do Rubber Keypads Normally Last in Devices?

Rubber keypads usually last in between 5 to one decade, relying on use, ecological factors, and quality of products made use of (Rubber Keypads). Normal wear and tear can shorten their lifespan, affecting functionality and individual experience over time

Can Rubber Keypads Be Personalized for Particular Applications?

Rubber keypads can undoubtedly be tailored for specific applications, enabling changes in dimension, form, appearance, and color. This versatility allows producers to develop customized remedies that meet diverse user demands and enhance capability in various devices.

Are Rubber Keypads Ecologically Friendly?

Rubber keypads are often not taken into consideration eco-friendly because of their petroleum-based products. However, improvements in lasting manufacturing methods and the advancement of bio-based choices are slowly improving their eco-friendly impact in different applications.

What Are Common Problems Faced Throughout Rubber Keypad Production?

Common concerns faced during rubber keypad production include irregular material top quality, mold and mildew flaws, incorrect curing times, attachment failures, and difficulties in attaining exact responsive responses. These troubles can cause decreased item efficiency and client dissatisfaction.

Just How Do Rubber Keypads Contrast to Other Kinds of Trick Switches?

Rubber keypads provide a softer feeling and quieter operation contrasted to mechanical buttons, which give responsive feedback. However, rubber keypads might wear out faster and do not have the accuracy that some individuals choose in high-performance applications.

The primary product used in the production of rubber keypads is silicone rubber, known for its outstanding strength and flexibility. When developing rubber keypads, the design procedure plays a crucial duty in identifying functionality and user experience. Rubber keypads significantly affect customer experience via their boosted tactile feedback, which allows for more specific interaction. Customers typically report greater contentment and effectiveness when communicating with gadgets that include well-designed rubber keypads, as they help with quicker and more exact input. A vital element of customer experience with rubber keypads exists in like this their longevity and longevity.